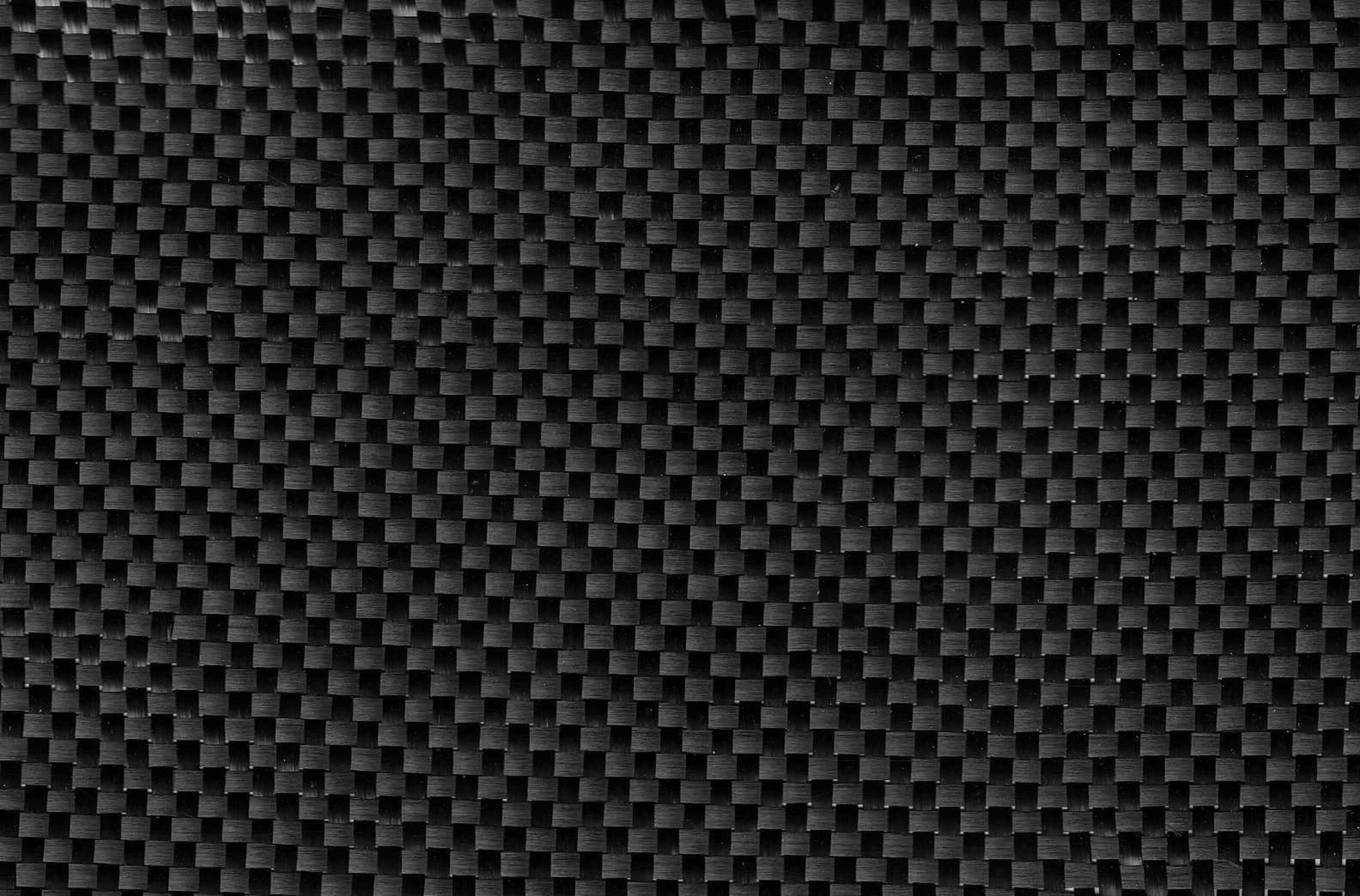

When it comes to design elements, few can match the versatility and appeal of carbon texture. From automotive to interior design, carbon texture has become a popular choice for adding a touch of sophistication and modernity to various products and spaces. In this article, we will explore the origins of carbon texture, its applications in different industries, and the reasons behind its enduring popularity.

The Origins of Carbon Texture

Carbon texture, also known as carbon fiber texture, traces its roots back to the development of carbon fiber composites in the mid-20th century. Carbon fiber composites were initially created for aerospace applications, where their high strength-to-weight ratio proved invaluable for aircraft construction. Over time, designers and engineers recognized the aesthetic appeal of the material’s unique pattern and began incorporating it into various industries.

Carbon texture is created by weaving or laying down thin strands of carbon fibers and impregnating them with a polymer resin. The resulting material is then cured and polished to achieve a glossy finish. The distinctive pattern of carbon texture is a result of the weaving process, where the fibers overlap and create a visually striking effect.

Applications in Automotive Industry

One of the industries where carbon texture has gained significant traction is the automotive sector. Carbon fiber components are now commonly used in high-performance and luxury cars to enhance their performance, reduce weight, and add a touch of elegance. From hoods and spoilers to interior trims and dashboards, carbon texture can be found in various parts of a vehicle.

For example, the Bugatti Veyron, one of the fastest production cars in the world, features carbon fiber body panels that not only contribute to its aerodynamic performance but also add a sleek and futuristic look. Similarly, the interior of the McLaren P1 showcases carbon texture extensively, creating a luxurious and sporty ambiance.

The use of carbon texture in the automotive industry is not limited to high-end vehicles. Many mainstream car manufacturers have also embraced carbon fiber composites to improve fuel efficiency and reduce emissions. The BMW i3, for instance, incorporates carbon fiber reinforced plastic (CFRP) in its construction, making it lighter and more energy-efficient.

Influence on Interior Design

Beyond the automotive industry, carbon texture has made its way into the world of interior design. From furniture to home accessories, designers are using carbon texture to create visually captivating spaces. The unique pattern and glossy finish of carbon texture add a sense of luxury and sophistication to any interior.

Carbon texture is often used in furniture design to create statement pieces that catch the eye. Chairs, tables, and even cabinets made with carbon fiber composites offer a sleek and modern look, making them ideal for contemporary interiors. Additionally, carbon texture can be applied to decorative items such as vases, lamps, and wall panels, adding a touch of elegance and visual interest.

Advantages of Carbon Texture

There are several reasons behind the enduring popularity of carbon texture:

- Strength and Durability: Carbon fiber composites are known for their exceptional strength-to-weight ratio, making them stronger than steel while being significantly lighter.

- Lightweight: The lightweight nature of carbon fiber composites makes them ideal for applications where weight reduction is crucial, such as automotive and aerospace industries.

- Visual Appeal: The unique pattern and glossy finish of carbon texture add a touch of elegance and sophistication to any product or space.

- Flexibility: Carbon fiber composites can be molded into various shapes and sizes, allowing designers to create complex and intricate designs.

- Resistance: Carbon fiber composites are highly resistant to corrosion, chemicals, and extreme temperatures, making them suitable for a wide range of environments.

Challenges and Limitations

While carbon texture offers numerous advantages, it also comes with certain challenges and limitations that designers and manufacturers need to consider:

- Cost: Carbon fiber composites are generally more expensive than traditional materials, making them less accessible for mass production.

- Production Complexity: The manufacturing process of carbon fiber composites requires specialized equipment and skilled labor, increasing production costs and lead times.

- Environmental Impact: The production of carbon fiber composites involves energy-intensive processes and the use of chemicals, raising concerns about its environmental footprint.

- Repair and Maintenance: Unlike traditional materials, carbon fiber composites are not easily repaired and may require specialized expertise for maintenance.

Future Trends and Innovations

As technology advances and manufacturing processes become more efficient, carbon texture is expected to become more accessible and affordable. With the growing demand for sustainable materials, researchers are also exploring the use of bio-based carbon fibers as an alternative to petroleum-based ones, further reducing the environmental impact of carbon texture.

Additionally, advancements in 3D printing technology have opened up new possibilities for creating complex carbon fiber structures. By combining 3D printing with carbon fiber composites, designers can fabricate highly customized and lightweight parts with intricate geometries.

Conclusion

Carbon texture has emerged as a versatile and innovative design element, finding applications in various industries such as automotive and interior design. Its unique pattern, glossy finish, and exceptional strength-to-weight ratio make it an attractive choice for designers looking to add a touch of elegance and modernity to their products and spaces.

While carbon texture presents challenges in terms of cost, production complexity, and environmental impact, ongoing research and technological advancements are addressing these limitations. The future of carbon texture looks promising, with increased accessibility, affordability, and sustainability on the horizon.

FAQs

1. How is carbon texture different from carbon fiber?

Carbon texture refers to the unique pattern and glossy finish created by weaving carbon fibers, while carbon fiber is the actual material made from thin strands of carbon.

2. Can carbon texture be used outdoors?

Yes, carbon texture is highly resistant to corrosion and extreme temperatures, making it suitable for outdoor applications.

3. Are there any alternatives to carbon texture?

Yes, there are alternative materials that mimic the appearance of carbon texture, such as vinyl wraps and hydrographic films. However, these alternatives do not offer the same strength and durability as carbon fiber composites.

4. Can carbon texture be customized?

Yes, carbon texture can be customized to a certain extent. The weaving pattern, color, and finish can be tailored to meet the specific design requirements.

5. Is carbon texture sustainable?

While the production of carbon fiber composites has environmental implications, ongoing research is focused on developing sustainable alternatives, such as bio-based carbon fibers, to reduce the carbon footprint of carbon texture.

Summary

Carbon texture, derived from carbon fiber composites, has become a popular and versatile design element in various industries. From automotive applications to interior design, carbon texture offers a unique pattern, glossy finish, and exceptional strength-to-weight ratio. Its visual appeal, combined with its lightweight and durable nature, has made it a sought-after choice for designers and manufacturers. While challenges such as cost and environmental impact exist, ongoing advancements in technology and research are addressing these limitations. The future of carbon texture looks promising, with increased accessibility, affordability, and sustainability on the horizon.